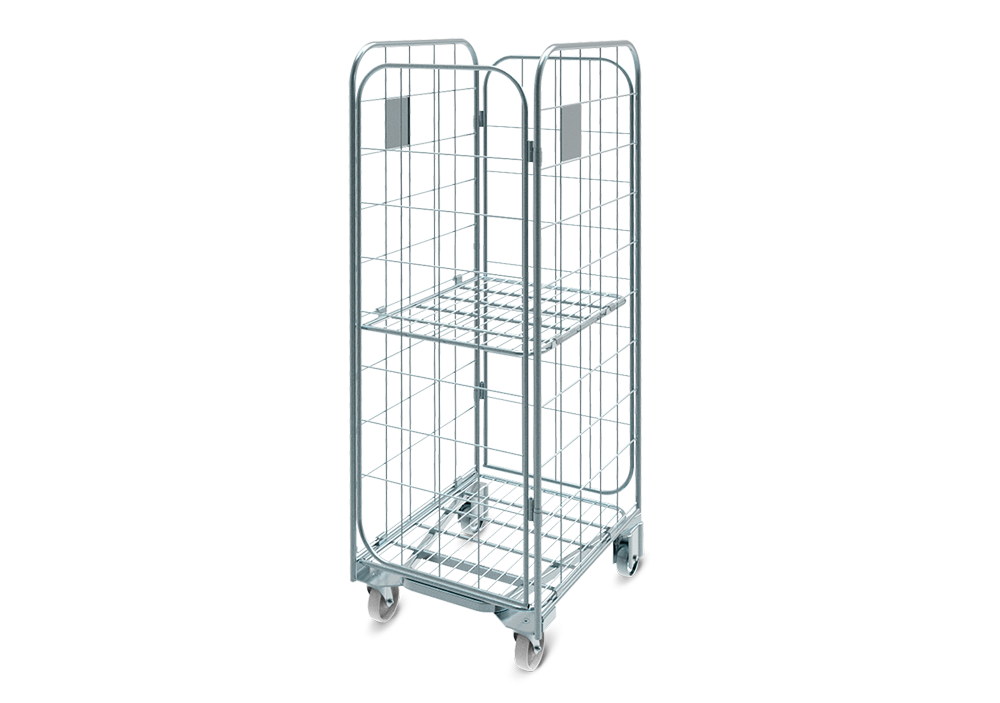

Roll-containers

Roll-container (roll cage) is a shipping container, used to protect goods of different weight, volume and shape from damages that could be caused during transportation and other loads handling. Utilizing of roll-containers enables effective order batching and transportation of products in small-size containers from the distribution center (DC) to supermarkets or from supplier to the customer.

How roll-container can be applied

Loaded roll-containers are moved to the shipping area of the warehouse. Then, they are moved to the truck on its wheels without use of manual pallet jack and forklift, and when arrived, roll-containers are wheeled out to the trading floor and discharged, goods are been laid out directly on the shelves. As a result, goods can be delivered within a short time via trucks to many outlets due to the significant economy of time needed for loading-unloading.

The design of roll-container

The meshed container structure was designed to carry goods up to 500 kg, overall dimensions are best for full load of the truck. «Ipris Profil» Ltd. is producing two types of meshed containers:

- nestable roll-container (comes with a lifting shelf),

- demountable (sectional) roll-container.

Advantages of using roll-containers:

- mobility, requires small amount of time to move in the stock and on the selling floor;

- possibility to transport goods without use of handling equipment;

- ensures the integrity and marketable state of products while delivering them to the end customer;

- possibility to deliver unpacked loads and goods in a soft package;

- minimization of errors in order batching and entrance of stock changes under wrong heading;

- the use of four walls enables to eliminate the expenditures on the stretch film;

- economy on labor hours.

Roll-containers of any type can be entirely disassembled and stacked.

|

|

|

|

|

|